Materials Consulting for Preserve Products (Fall 2010)

Preserve Products is considering including calcium carbonate filler in its Everyday Plate product. My team evaluated the effect of various filler concentrations on product performance and gave our recommendations to the company.

The GoalPreserve Products is a sustainable-minded company located in Waltham, MA, which produces consumer products made from recycled polypropylene (PP) plastic. They sought a team of students to investigate the usage of calcium carbonate filler in their Everyday Plate product line to decrease both the cost and the environmental impact of the product.

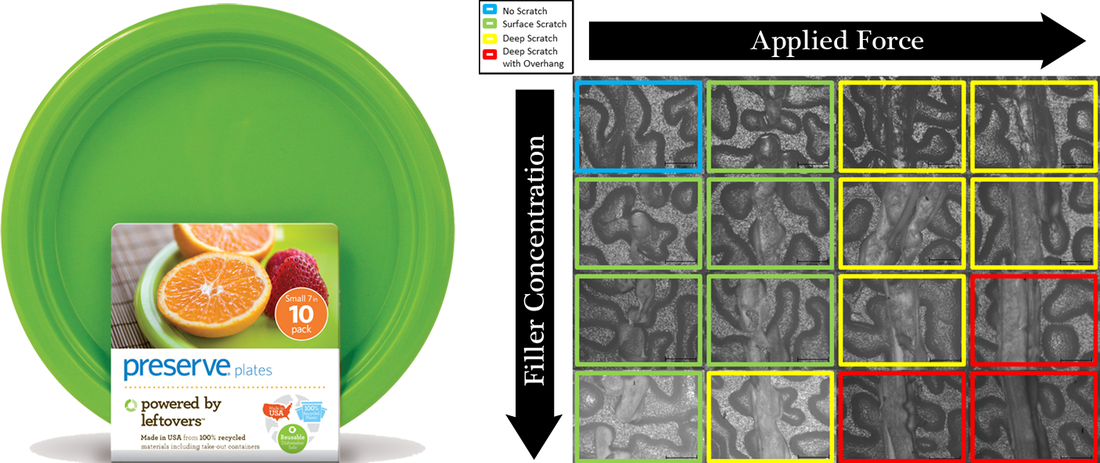

The ProcessThe purpose of our investigations was to determine the effect of filler concentration on product performance. Product failure does not occur only in the event of mechanical failure under expected use conditions. Aesthetic failure has the same end result: a discarded product. To evaluate product performance, we designed and performed an array of tests on samples of plates with different filler concentrations.

|

The SolutionAfter performing a series of mechanical, thermal, and aesthetic tests, we came to the conclusion that aesthetic failure would limit the concentration of calcium carbonate filler. Samples with higher concentrations of filler showed highly visible surface scratching under normal use conditions. We recommended a low concentration of filler for use in the Everyday Plate. Higher concentrations could be used in other products in which surface abrasion is less likely and appearance is less important..

My Responsibilities

|